What are the processing ranges for sheet metal chassis casings?

At present, the processing industry of sheet metal chassis shells involves various processing methods, and sheet metal processing is one of the more common processing methods. In the processing and production process, workers need to first learn processing techniques to ensure the processing quality and accuracy of sheet metal shell materials. This processing method involves a lot of content. When processing the shell of a sheet metal chassis, the process of cutting and other processes can be completed. Through these processing steps, production objectives can be achieved. Workers also need to pay attention to mastering parameter characteristics and process methods during processing and production. These are important aspects that cannot be ignored.

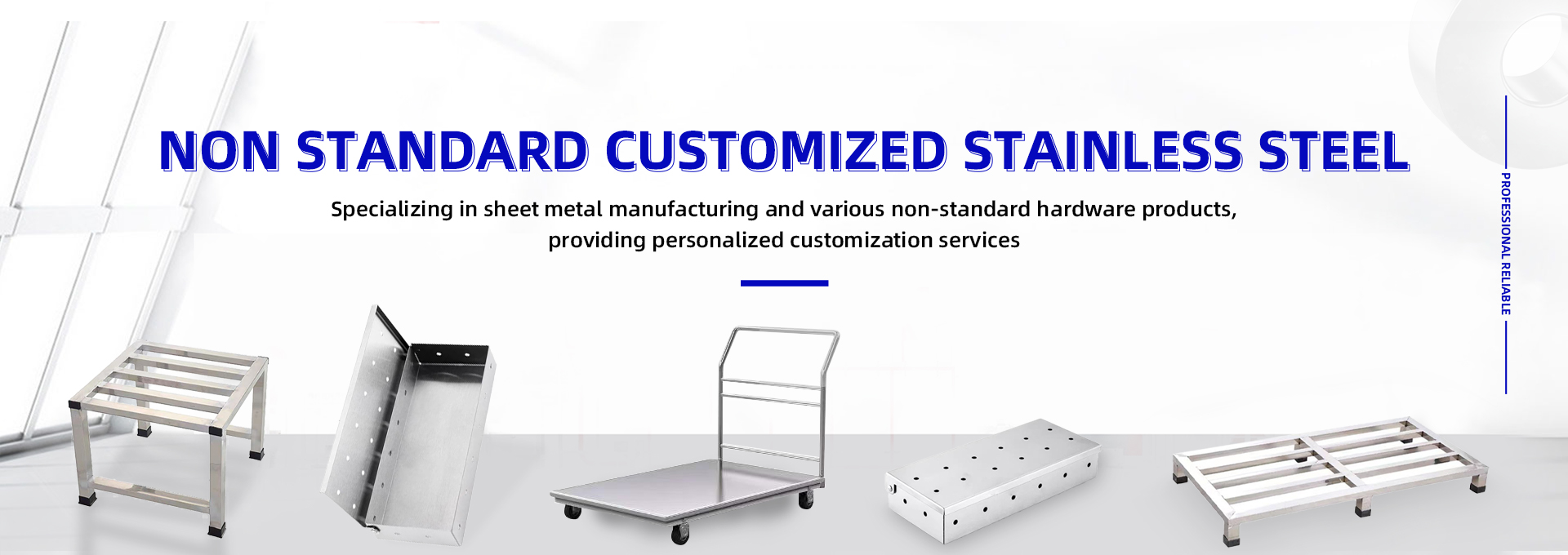

However, before processing the casing, workers need to know the processing range. Generally speaking, copper products, galvanized sheets, stainless steel, and other materials can be selected to complete the processing flow during the processing operation. Therefore, this processing method has a wide range and can also meet the processing and production requirements of different industries. During the processing, people can flexibly choose materials without worrying about materials not meeting processing requirements and affecting the progress of production tasks.

There are still several issues to be noted in the processing of sheet metal shells. Firstly, the staff should inspect the materials before processing and carry out the material processing. The unfolding method of materials should be correct in order to save materials during the processing and achieve the processing objectives. During the processing, attention should also be paid to the selection of gaps and the winding effect of materials.